This leg of our journey had us staying at Arnold AFB (A.E.D.C.) Recreation Area near Tullahoma Tennessee. We were there for six weeks.

It doesn't look like much, but it had a great view of the lake. We were sitting off the main road through this section of the campground. Some of you may remember what FHU means, for those that don't, it means Full Hook-Up... which we didn't have. It was necessary for me to dump the black tank (toilet) once a week, I did the gray (shower and sinks) twice a week for convenience.The nice part about getting out of the city is the opportunity to enjoy nature up close.I know it is hard to see, but the bird sitting on the dock is a blue heron, which appeared to have a nest somewhere in the cove we were at.

I even did a little fishing while we there. There a spot on the shore that had some old steps that led to the water... great for fishing. If you must, please re-read the previous sentence, I said "I did a little fishing". There was a large school of these baby fish swimming around my feet. The nice part about this lake... no poisonous snakes swimming around. In fact, a 50-yard walk from our site was the beach.

The table.

We put out walnuts and pecans, and watched the squirrels have a field day. Once we ran out of nuts, the entertainment ceased, after realizing the meal ticket expired.

We put out walnuts and pecans, and watched the squirrels have a field day. Once we ran out of nuts, the entertainment ceased, after realizing the meal ticket expired.

The birds were in abundance.

Daily we could hear the woodpeckers making holes, mostly in the utility poles.

Daily we could hear the woodpeckers making holes, mostly in the utility poles.

As a city boy, it was my first time actually seeing a Mayfly.

The first is a male, the other is a female. These two were speed dating on our rig. The female did not stay long, she got what she wanted and left, the male hung around looking for more love.

It wasn't all fun and games while we were here. Before winter last year we were on the other side of Tennessee, and I spoke to a metal fabricator about making a rack for the back of the trailer. He put me off for a couple of weeks before he finally admitted he really didn't want to do the job. We spring forward to spring, again in Tennessee, only this time we are on the west side of Tennessee. I contacted another metal fabricator, presented my design to him, and he accepted the job. I explained our time schedule, and in the end we cut it close, but the job was outstanding. I stopped in his shop several times to discuss progress and design modification, and when he came out to do the installation, we had a couple of more modifications... due to the first modifications.This rack was over engineered considering I only planned to carry our generator on it... but I am very happy with it.

It wasn't all fun and games while we were here. Before winter last year we were on the other side of Tennessee, and I spoke to a metal fabricator about making a rack for the back of the trailer. He put me off for a couple of weeks before he finally admitted he really didn't want to do the job. We spring forward to spring, again in Tennessee, only this time we are on the west side of Tennessee. I contacted another metal fabricator, presented my design to him, and he accepted the job. I explained our time schedule, and in the end we cut it close, but the job was outstanding. I stopped in his shop several times to discuss progress and design modification, and when he came out to do the installation, we had a couple of more modifications... due to the first modifications.This rack was over engineered considering I only planned to carry our generator on it... but I am very happy with it.

There is a story that goes with this rack. I told the owner of Family Fabrication, LLC that I would pick up the metal for him. Carol and I arrived at the metal supply shop, placed the order, and the shop guys took the order to our truck. This is where it got sticky... the tailgate opening mechanism decided to break... I couldn't open the tailgate. I went back into the office and told the fabricator they were going to need to pick up the material. Missionaccomplished. The rack is installed so that the rack portion can be removed if necessary.

The deal I made with the owners was, they bring the whole family down to the campground, and the children could play while dad and I installed the rack. It was a great time for all of us. I smoked a pork loin, and cooked some hot dogs.

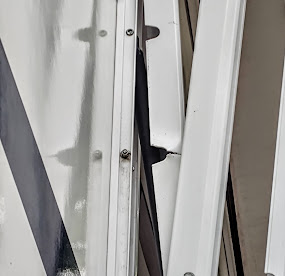

While waiting for he rack installation I had a repair to make myself.

If you look closely you will note cracks on the supports. This damage occurred last year when we were visiting the grandchildren in Wisconsin. We had the awning out, a shade screen was attached to it, and they were both secured to the ground. Well... one night it decided to rain really really hard, and the wind rode in, and at one point a gust apparently forced the awning up, then back down, causing the cracks.I went out to the hardware store and bought some aluminum strapping, and riveted it to the support rail on both sides of the two damaged rails.

If you look closely you will note cracks on the supports. This damage occurred last year when we were visiting the grandchildren in Wisconsin. We had the awning out, a shade screen was attached to it, and they were both secured to the ground. Well... one night it decided to rain really really hard, and the wind rode in, and at one point a gust apparently forced the awning up, then back down, causing the cracks.I went out to the hardware store and bought some aluminum strapping, and riveted it to the support rail on both sides of the two damaged rails.

We are currently discussing replacing the awning with one from a different manufacturer, and adding window awnings on the windows on the opposite side of the trailer.

One day I took a walk to the other side of the cove, which was a sailing club. When I got here it looked more like a dead sailboat fleet. The club has a beach, picnic area, and some camping sites... and lots of boats that need love.This is looking over to our site. Can't see it can you, that's because of the trees that provide privacy.

We did find time to play a bit. Most of what we did was small local stops, one of which was Walgreens for mail, another was the base commissary and exchange. This base was decommissioned back in the 90s, and predominately does development now, hence, A.E.D.C.. So, back to the commissary and exchange. The commissary is the size of a medium sized mom-and-pop grocery store, and the exchange was half that size, with a third of it being alcohol.

Forward Thinking

One of our day outings was to a state park in Tullahoma. The park had hiking trails and three waterfalls, we only hiked to one of them. Walking the trail we ran across some interesting species of plants.

The trails were covered by trees providing lots of shade, which was a good thing, because the day got hot... and it was early in the day.This guy was making his way up a tree as I was going down a trail. You might recognize him, he is a millipede, his round body and many legs give him away.

Speaking of trails, I was the only one that actually made it to the waterfall. I started down the trail and steps first to see if it would be safe for Carol to hike. The trail bordered on hard to difficult. The steps were either tree roots or stones, of which some were natural placement, other were put in place by humanoids. I had to be really careful on the way down because the rock steps were slippery due to a previous rain.

Once down to stream level, it was necessary to navigate the stream to get to the waterfall.

The stream was not fast moving water, and easy to cross from one side to the other via stepping stones. The walk from the last step of the path down was approximately 200 yards to Machine Falls. Apparently none of the falls are huge, so it is easy to get close to them. I was able to walk the rocks and get in front of the falls for a couple ofpictures.

The stream was not fast moving water, and easy to cross from one side to the other via stepping stones. The walk from the last step of the path down was approximately 200 yards to Machine Falls. Apparently none of the falls are huge, so it is easy to get close to them. I was able to walk the rocks and get in front of the falls for a couple ofpictures.

The blurry photo was taken when I was standing on a rock in front of the waterfall. The hike back was just as challenging as the hike down. It was a fun day trip.

One day we had a torrential rain, and needed to watch the truck for flooding. A few years ago we had the windshield replaced because of a rock chip that hit too low on the windshield, running to the windshield edge. Traveling in areas that didn't get much rain we never learned of the possible leak. As we traveled through the South, the rains increased so much that it apparently found a way in at the top of the windshield.

Surprisingly the storm didn't run into the truck... so I thought. A couple of days after the rain I was getting into the back seat of the truck, and heard a sloshing sound.

We did travel to Lynchburg for a tour at the Jack Daniel's Distillery. Getting to the distillery early was a great idea on our part the day we went. There isn't much parking in front of the distillery, so we parked across the street, which was advantageous, due to the size of the truck. The starting part of the tour begins at the small museum.

Jack Daniel's whiskey started on a farm of a minister. As a boy Jack was sent to live on the farm of this minister. Jack took a liking to the tender of the minister's still. The gentleman making the whiskey, was named Nathan "Nearest" Green, a slave. Nearest took jack under his wing and taught him everything he knew about making whiskey.

After the Civil War, Jack bought the minister's still, and hired Nearest as his first Master Distiller. Eventually Jack moved the distillery to its current location in Cave spring Hollow.

This is one of the few photos I could take... because it was the museum portion of the tour. This is a model of the distilling process.

Starting at #1, is the milling stones for grinding the three types of grain used to make Jake Daniel's Tennessee whiskey, corn, rye, and barley. Mr. Jack formed the recipe himself. Around 1900 they changed over to steel grinding mechanisms. Using the steel grinding mechanism provides a more consistent fine grind. The ground grain is mixed with spring water from Cave Spring on the property, and a bit of whiskey from a previous batch. This "mash" is then sent to the mash cooker (#2), and cooked over a high heat.

That cooked mash moves over to the fermenting vat (#3), where yeast is added, and allowed to ferment for approximately six days. Many of you may know what happens when the yeast is added to the mash, but for those who do not, it changes the sugars in the mash to alcohol and carbon dioxide. This process generates a lot of heat, so there are cooling coils within the vat to ensure the temperature is kept close to 85℉. This resulting liquid is known as "distiller's beer", and pumped to the still (#4). The still is heated, and since the boiling temperature for alcohol is a lower temperature than water, it turns into steam and rises to the top of the still, working its way down. On its way down it condenses back into liquid again. At this point the alcohol is running around 140 proof.

The mellowing vats (#5) is where Jack Daniel's becomes a different whiskey from the others. The product slowly drops ten feet, one drop at a time, through charcoal filtering. When I say slow, I mean slow... one drop takes a day to get from top to bottom. The smooth, mellow spirit is then mixed with more spring water to lower the proof. The last step is moving the spirits to charred white oak barrels (#6), made on site. Once in barrels they will be taken to the barrel warehouse for aging, which will vary with the variety distilled. What makes their whiskey distinctive is seasonal temperature changes, which forces the whiskey in and out of the wood.

Something I did not know: If you look towards the bottom of the photo, you will notice cases of beer, that's right, beer. Jack Daniel's produced their beer from 1992 to 1998.

Once the guided portion of the tour started, there is no picture taking allowed in the buildings. With that being said, we could take pictures outside. Our first stop was near one of the barrelwarehouses. There are over a dozen of these warehouse, each one holding thousands of barrels of aging whiskey.

The next stop was a pyromaniacs fantasy.Two guys sit all day, five days a week, burning oak pallets. What was interesting was the fact that it is a controlled burn. This charcoal is what will end up in mellowing vats.

A short walk took us to the distilling building where no photography is allowed. A memorable section was the fermenting vats... because a whiff of the process will clear visitor's nostrils for a long time. Walking out of the distilling building visitors see blackness all over the trees and buildings.The blackening is due to the distilling process. This discoloration can be seen in a one-mile radius of the distillery.

The spring actually starts a short ways back on the property. From here we turned around to meet the founder of the distillery himself.Jack was not a tall man, there is an outfit of his in the museum.

As usual, we paid for the tasting tour, so off to the tasting room. The room was located in one of the barrel warehouses. With each tasting came a story.

As usual, we paid for the tasting tour, so off to the tasting room. The room was located in one of the barrel warehouses. With each tasting came a story.

The second tasting has a story involving Frank Sinatra. Frank use to drink Jack Daniel's during his shows. An opened bottle would be brought for him by an assistant. Mr. Sinatra had a phobia... he would only take one drink from the bottle, and the remainder was shared with the audience. The blend is a special blend to his liking... and you can drink it too... at $150.00 a bottle. Jack Daniel's has a contract with the family, which will finally run out this year. The other tastings are a variety of their product, and one is a single malt rye.

Something Carol and I found interesting about the aging process of the barrels. During the aging process alcohol evaporates from each barrel. Our guide said that each barrel will produce between 65 and 80 bottles of whiskey, depending on where the barrel is stored in the warehouse. Each barrel generally starts out with about 90 bottles. If you are interested in purchasing a barrel of whiskey for a special event, prepare to pay close to $10,000.00; it hinges on how many bottles come out of the barrel.

Back in the museum building is the store for purchasing the fine spirits, and on the way are bottles of yesteryear. Believe it or not, we didn't buy any booze.

With this stay at an end, we are getting ready to head up to our annual RV rally in Lebanon, Tennessee.

No comments:

Post a Comment